Foodtech startup repurposes tobacco plants to create growth medium for cultivated meat

The repurposed tobacco plants yield a cost-effective growth factor that can then be used to grow cell-derived meat.

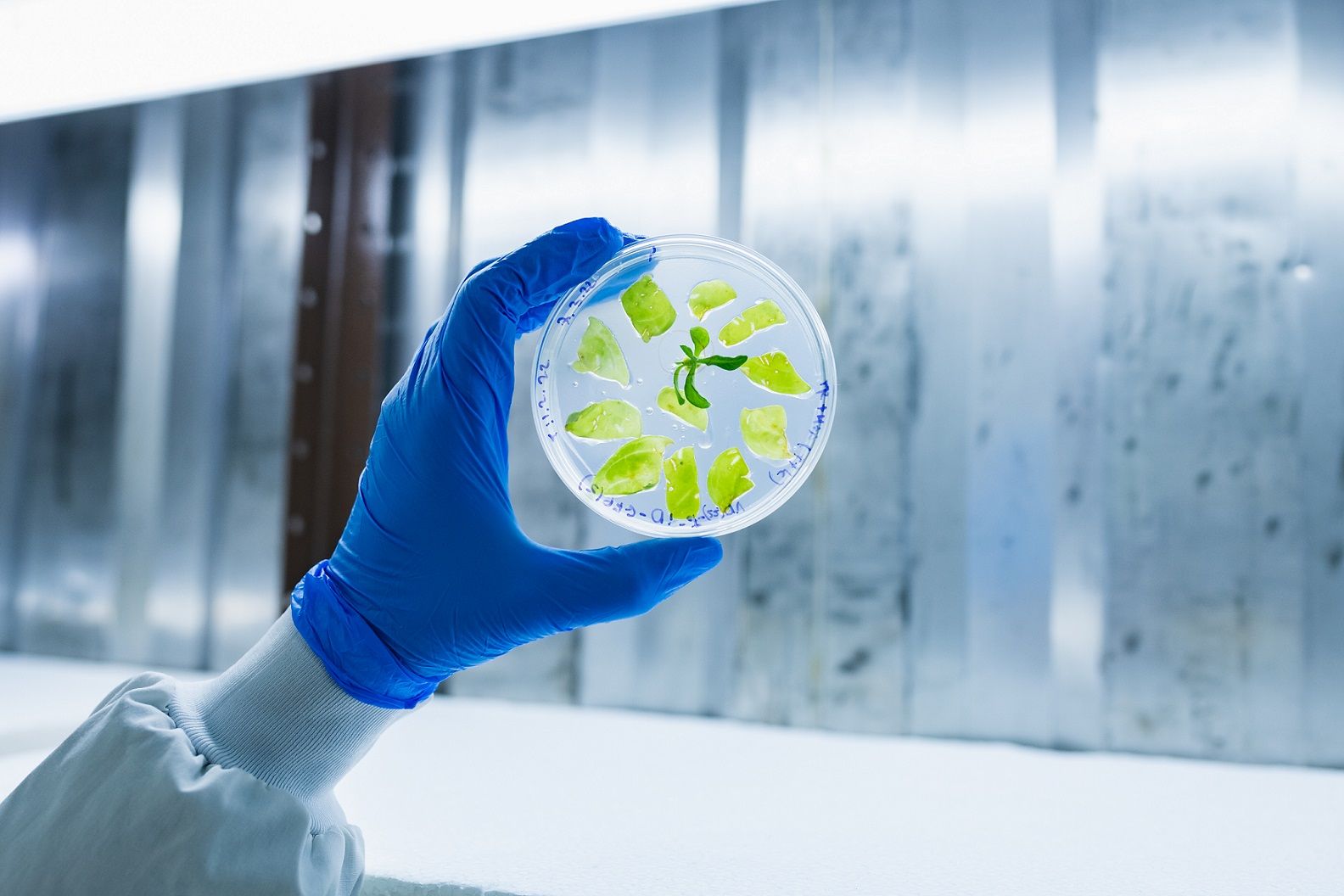

Photo from BioBetter Ltd.

Israeli foodtech startup BioBetter Ltd. is now using tobacco plants to create the growth factors needed to produce cultivated meat. Located in Kiryat Shemona, Israel, the company works to develop technologies for manufacturing proteins used in foodtech and other industries.

The repurposed tobacco plants (Nicotiana tabacum) yield a cost-effective growth factor that can then be used to grow cell-derived meat. As the company explained in a press release, “As numerous cultivated-meat startups move beyond the proof-of-concept phase, they run against one of the biggest challenges facing this budding industry. Developing a scalable and cost-effective production platform to make cultured meat affordable for the mass market has proven to be a primary stumbling block.”

The production of cell-derived meat requires a cultured medium comprising not only a mixture of amino acids and nutrients but also growth factors to make cells multiply. Producing these growth factors is a complex process. For instance, collecting growth factors such as insulin and transferrin from livestock is often cumbersome and difficult to do at large scale. Other growth factors can be produced by fermenting yeast or bacterial, but the company says the process is typically expensive, as is the cost of the purification process.

Instead, BioBetter is using tobacco plants to produce growth factors of non-animal origin. As the company explains on its website, “Our platform employs field-grown tobacco plants as a self-sustained, animal- and pollution-free, renewable energy-driven ‘bioreactors’ that constitutively express recombinant proteins with innate proprietary purification and integrated immunogenic sugar-removal mechanisms. These plant-based bioreactors provide a natural, efficient greenhouse gas sink, absorbing CO2 and releasing O2 back into the atmosphere.”

Producing growth factors in this way not only reduces the cost of producing cultivated meat but also allows companies to scale up production more quickly. It’s a solution that’s needed, explained Dana Yarden, MD, cofounder of BioBetter, in a press release. “The Good Food Institute determined that approximately a 100-fold reduction in insulin and transferrin costs is required to make cultivated meat economically viable. It is estimated that growth factors and cell-culture media can constitute 55% to 95% of the marginal cost in manufacturing cell-based foods,” says Yarden.

This initiative also gives tobacco plants another purpose. “There are multiple advantages to using Nicotiana tabacum as a hardy vector for producing [growth factors] of non-animal origin,” added Amit Yaari, PhD, CEO of BioBetter, in the press release. “It is an abundant crop that has no place in the food and feed chain due to its extremely bitter taste and content of undesirable alkaloids. The global trend for reducing tobacco smoking also is raising concerns among tobacco growers that the crop might eventually become obsolete. Yet the tobacco plant has huge potential to become a key component in the future of food. Tobacco plants can achieve up to four growth cycles annually and be harvested all year. This translates to more voluminous outputs per square meter of growing space.”

Epax launches concentrated oil that combines omegas 3, 9, and 11

May 10th 2024The blend of long-chain polyunsaturated fatty acids and long-chain monounsaturated fatty acids combines the heart and brain health benefits of omegas-3s with the skin and metabolic health benefits of omegas 9 and 11.